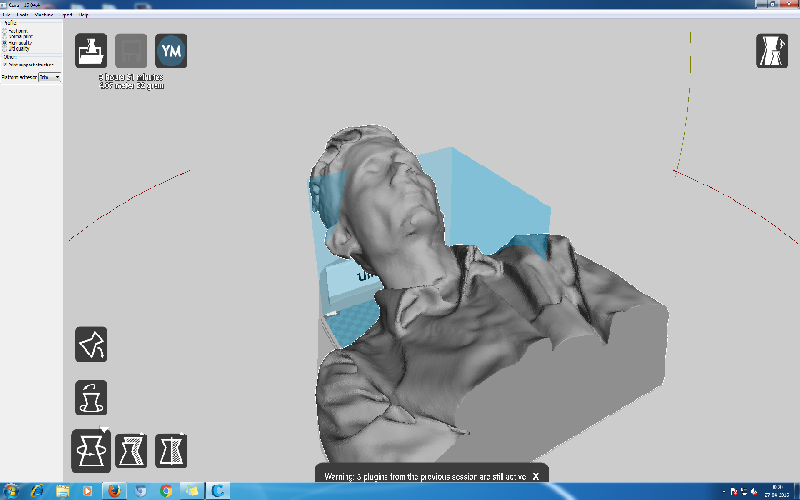

So for 3D scanning assignment we scanned our self from Sence scanner, and that this iam going to use for this assignment.

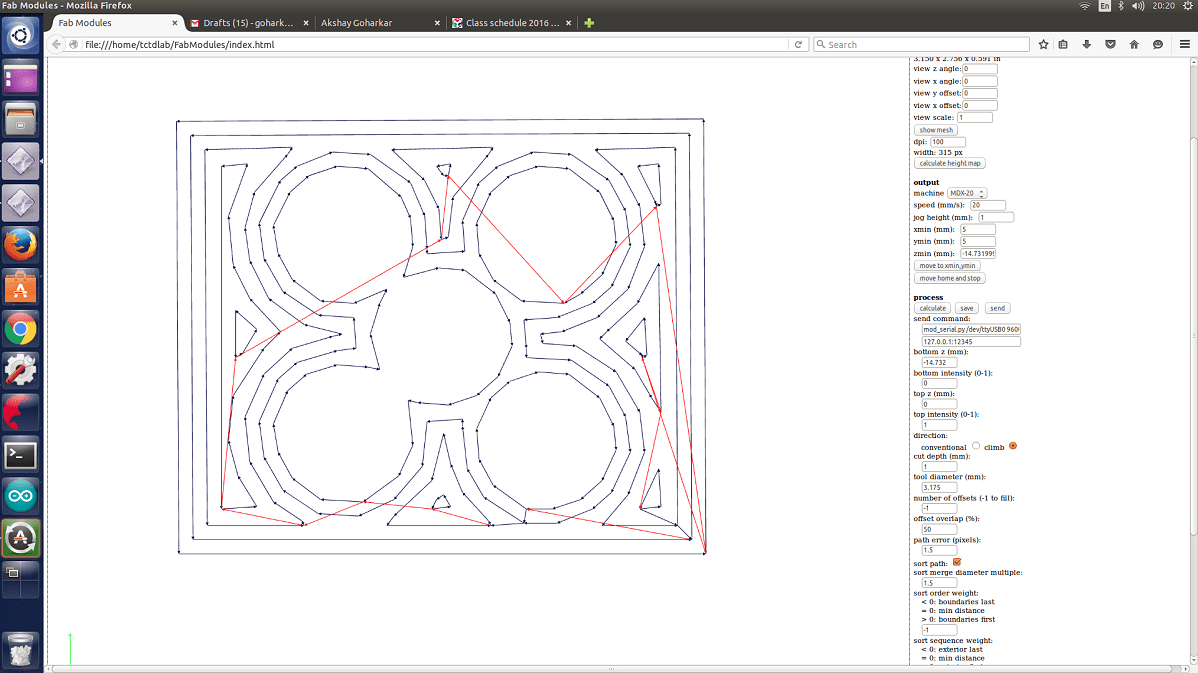

I downloaded the .stl file started the fab modules and imported into fab modules.

But unfortunately that files sizer are more than 200mm so its not fitting into the fab modules.

<>

<>

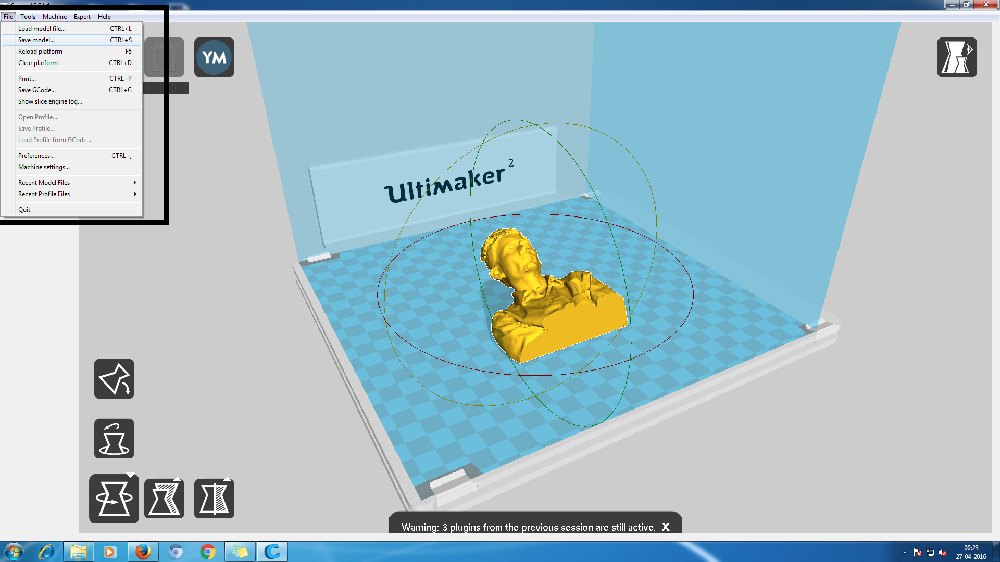

Then i started to finding the ways for scaling down that image, and firstly choosen the solid works, then Cura it scalled down in cura and saved into .stl file.

Then i restarted the fab modules and imported the .stl file, Now its showing me Loading stl file but nothing is comming there.

So my this idea also went wrong, But yeah i am trying some other softwares for scaling the lets see whats will be happen.

Then i started to make another design for molding in solidworoks then saved into .stl file.

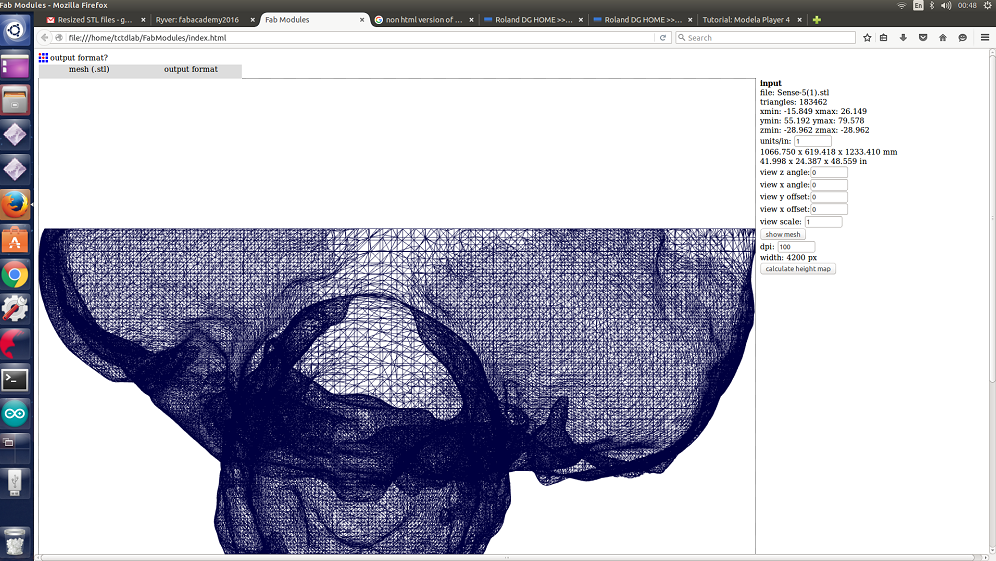

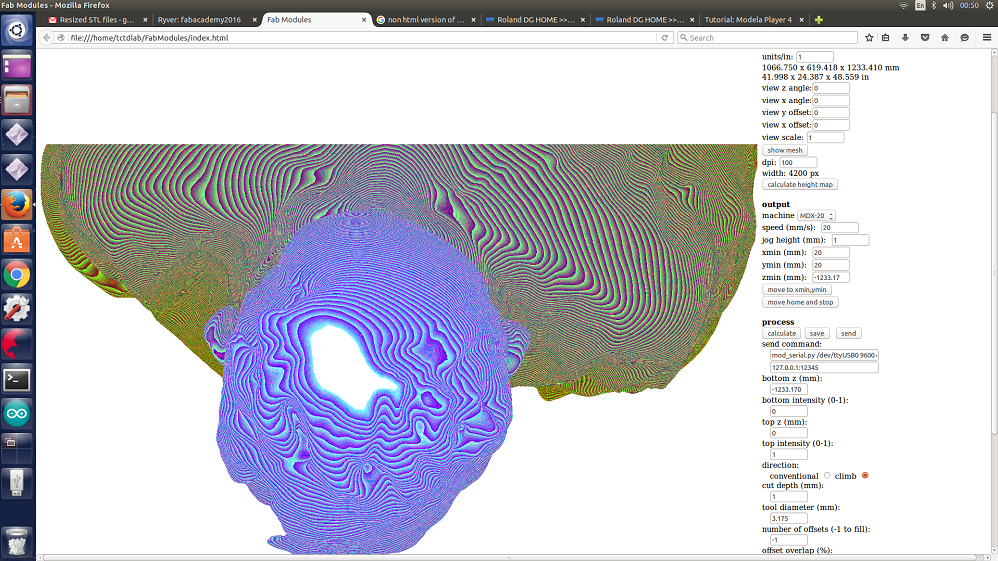

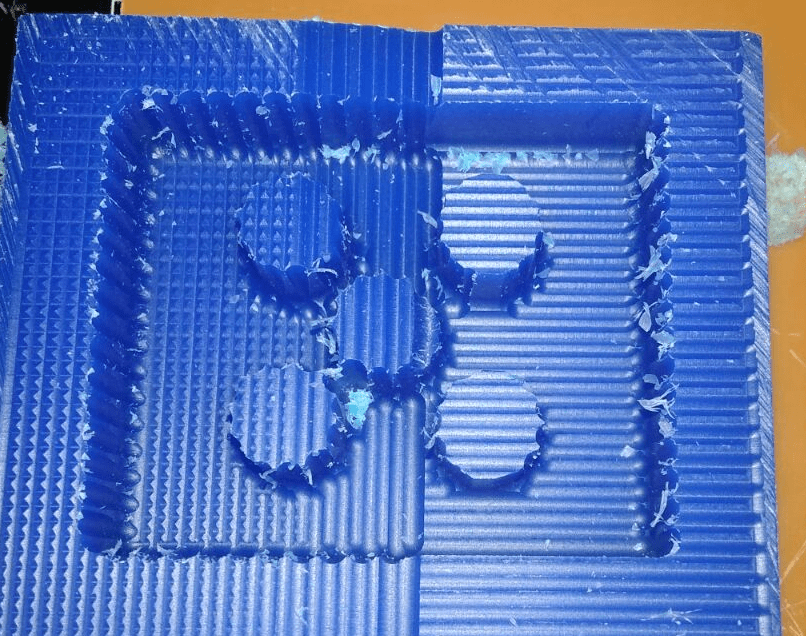

And now imported into fab modules then changes the X,Y directions for top view and all the parameters.

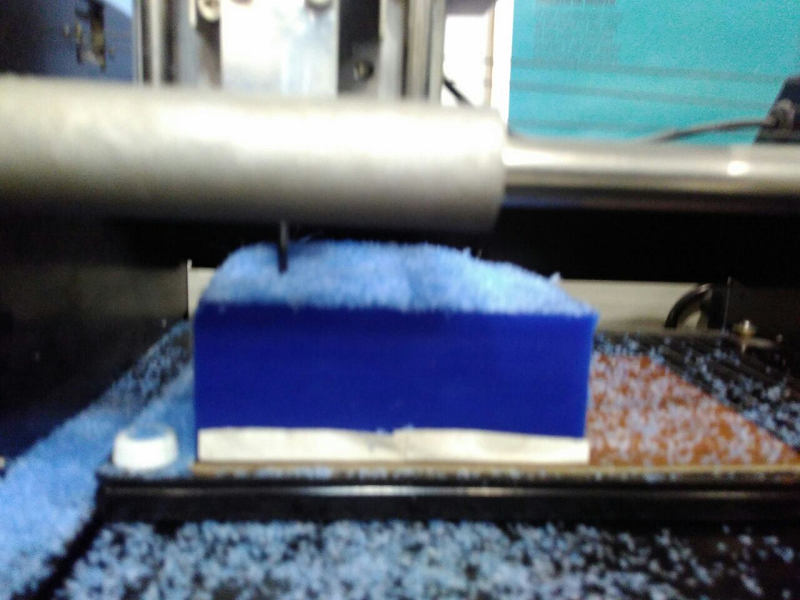

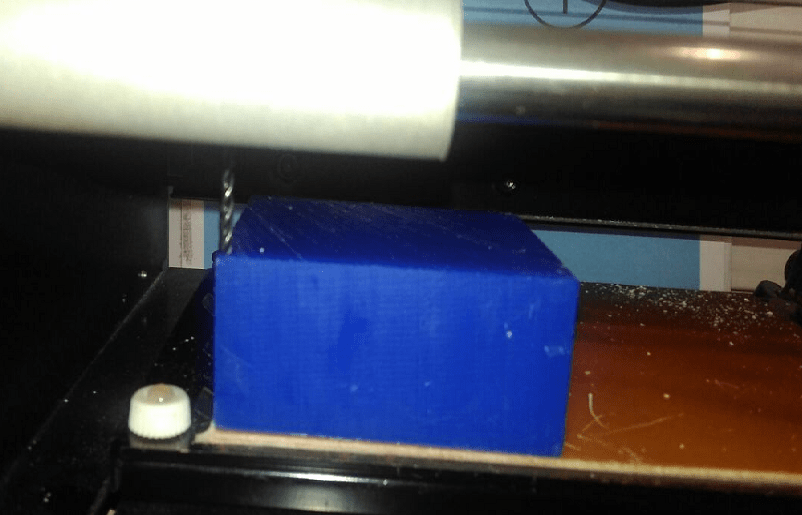

Now sticked the Wax on bed, changes the bit of 3mm rough cut, set the X,Y home and Made the Z zero, then calculated the all then just send.

After a 42 minutes it's done, Then went to finish cut it's also takes something 38 minutes, and finally its done.

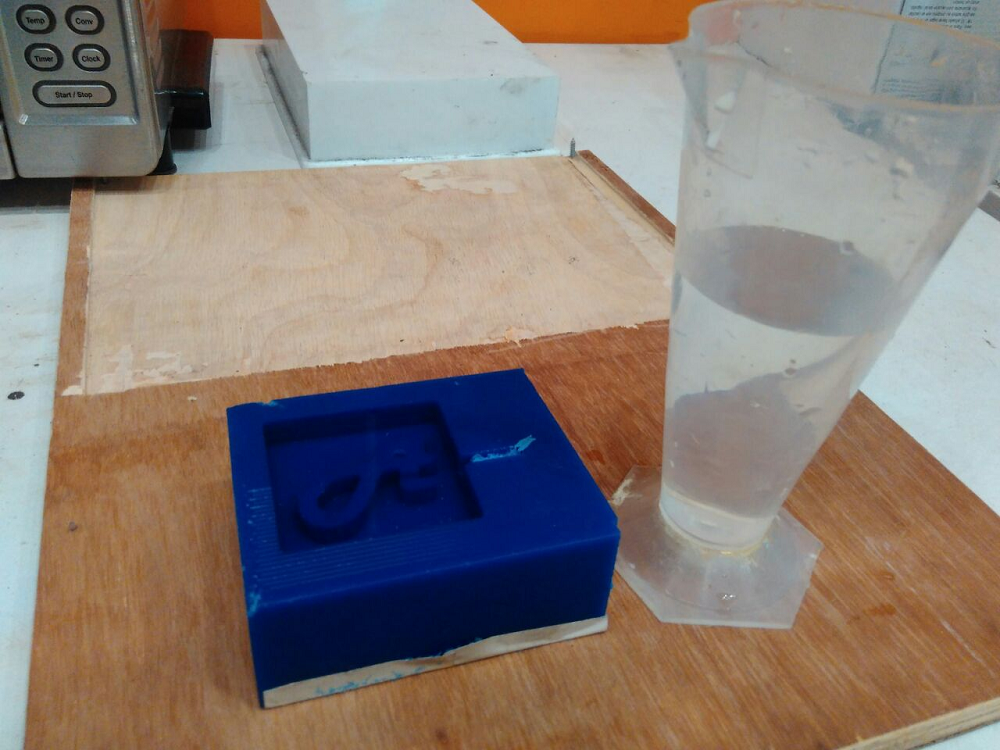

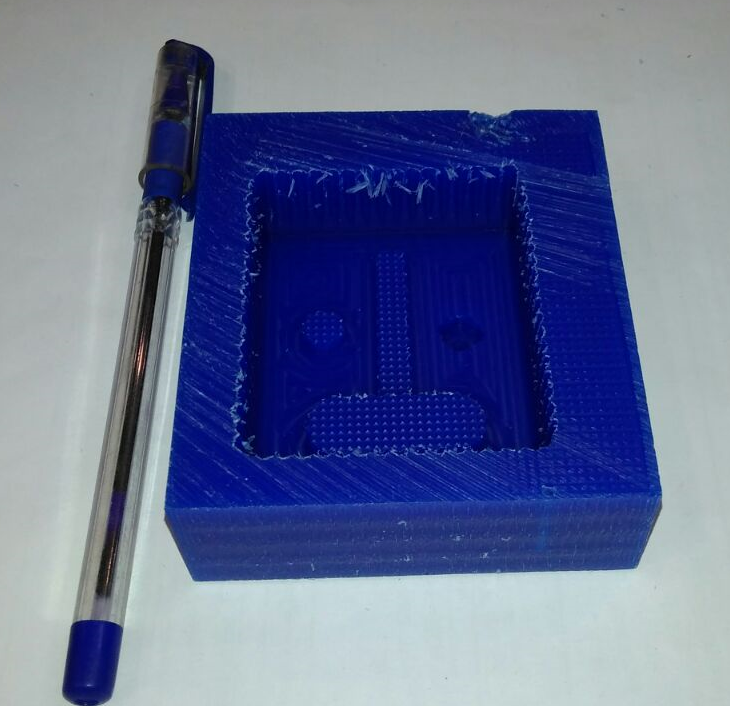

Just taken the Wax por it the water into that calculated the volume its 30ml.

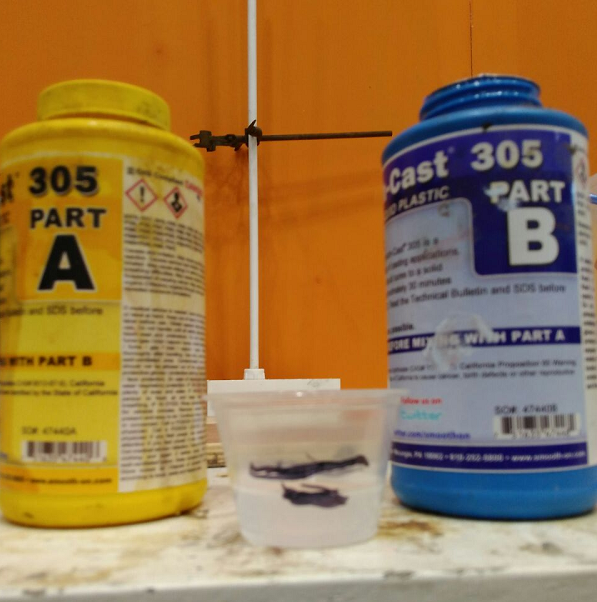

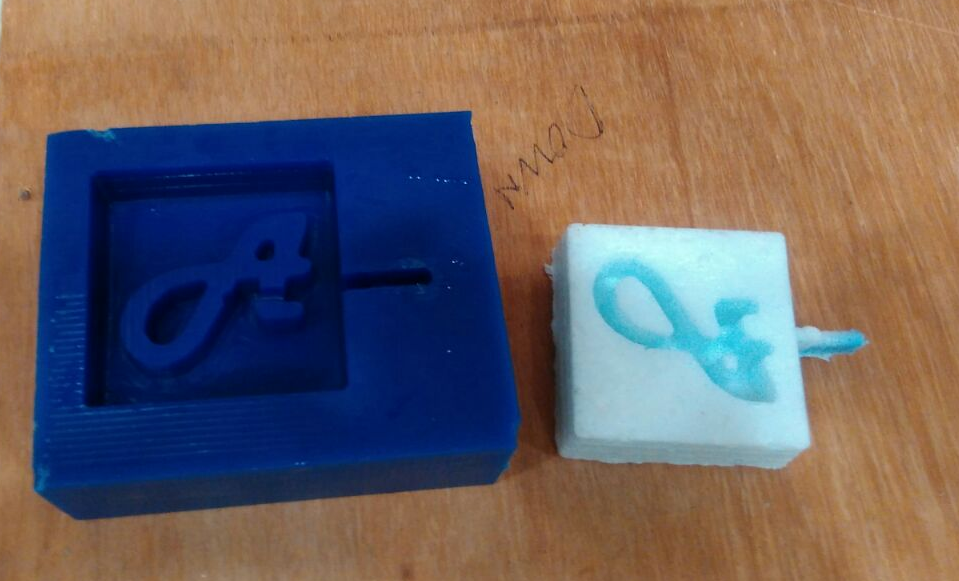

So i taken the Smooth-cast Bright white Liquid plastic Part-A, Part-B each 15-15 ml then mixed And port it into wax.

After 25minutes it comes and wow its just awesomely comes.

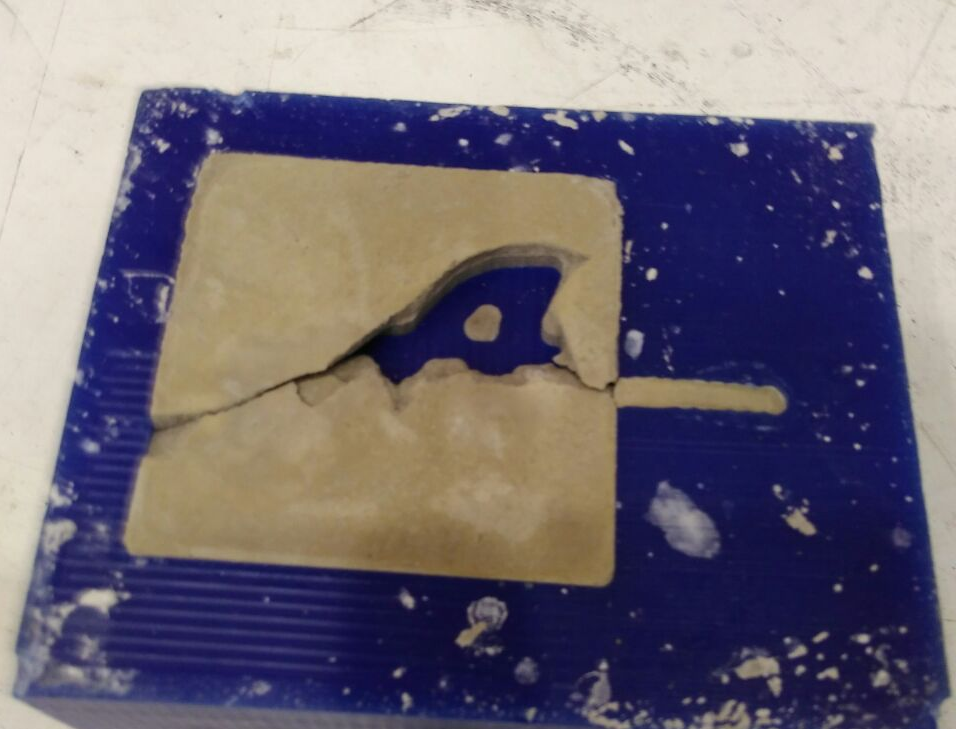

So as per Second pouring Hydro-stone(gypsum cement) Wait it for 30 minutes again, And now it's not comming just because of Hydro-stone is fixed very strongly.

But i didn't went like that So my Dry stone will got going to come out.

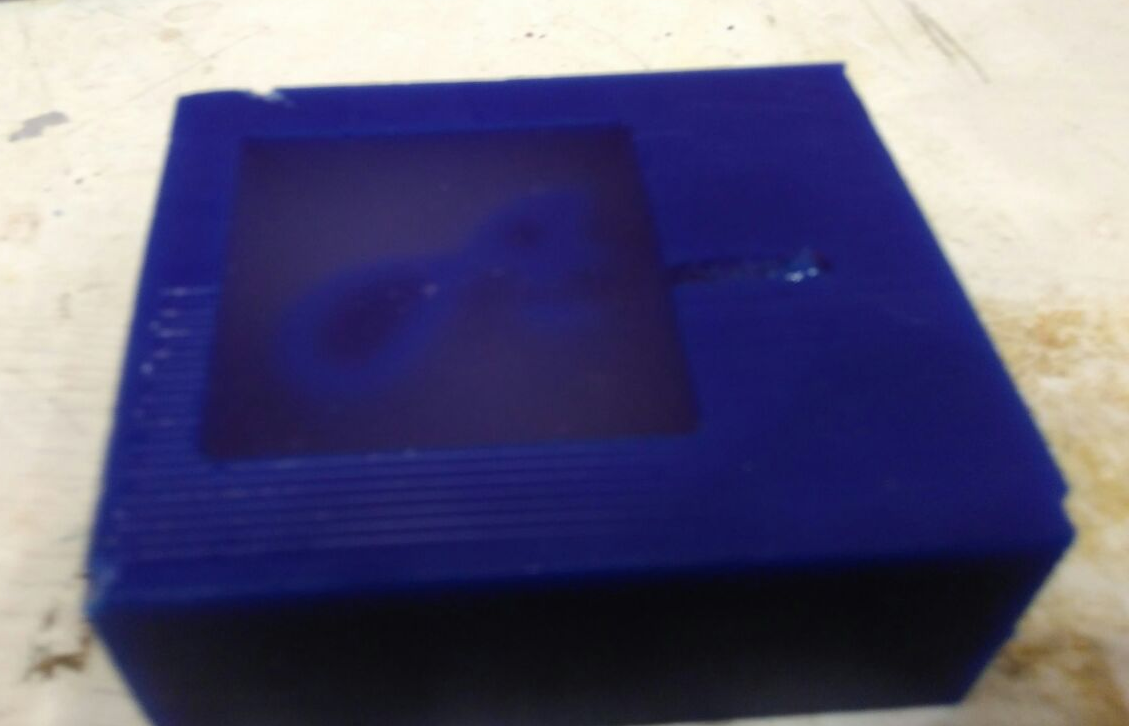

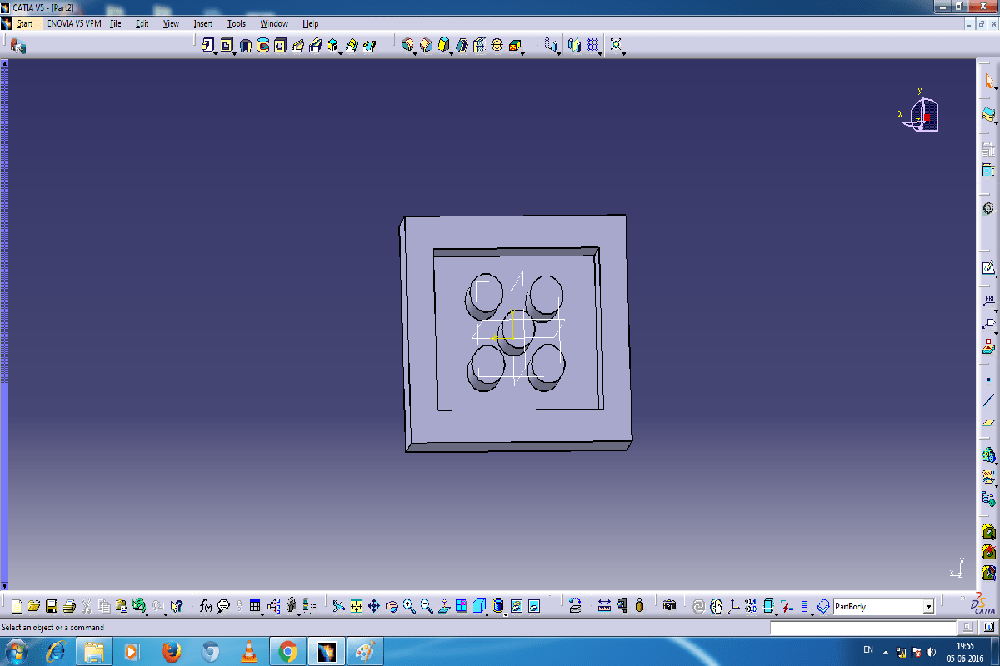

For second time a made another Design on Catia for molding and costing.

And saved into .stl file and imported into fab modules but its need binary stl.

So i imported this file into Cura and didn't saved into Binary stl.

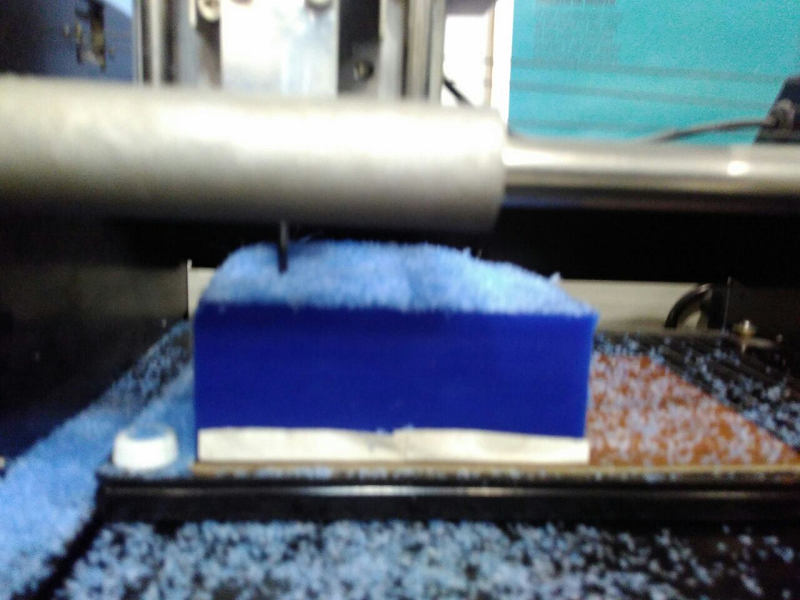

Then sticked the wax of 80*70mm and setted all the parameters, set the 1/8 Rough cut bit.

After all the setted the X,Y home position and Z manually calculated and then just go.

It takes 28minutes but comes very smoothlly, Then went with 1/8 finish cut bit it takes 19minutes.

Here unfortunately tool loosed and comes out so It happes Like that

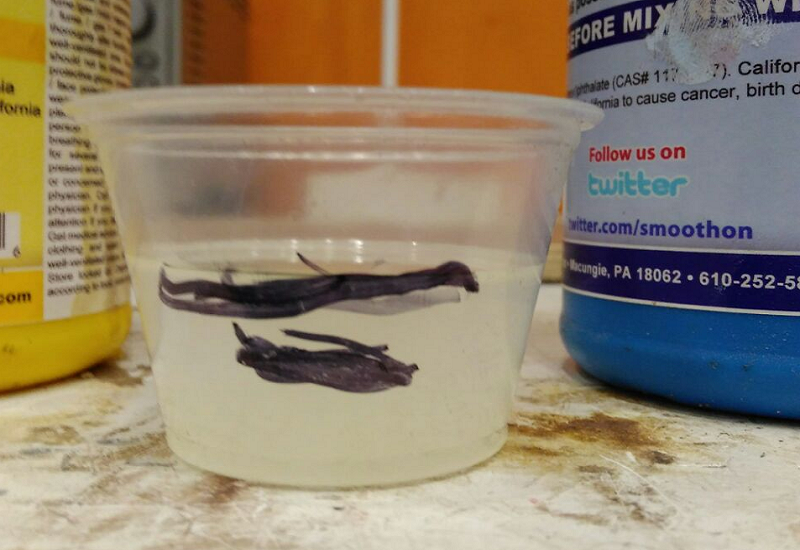

But i pored the Silicon rubber its hassent come properly just beacuse i dint pored the Part B in perfect Qwantity

So we order the new silicon rubber from india Silicon rubber link for indians

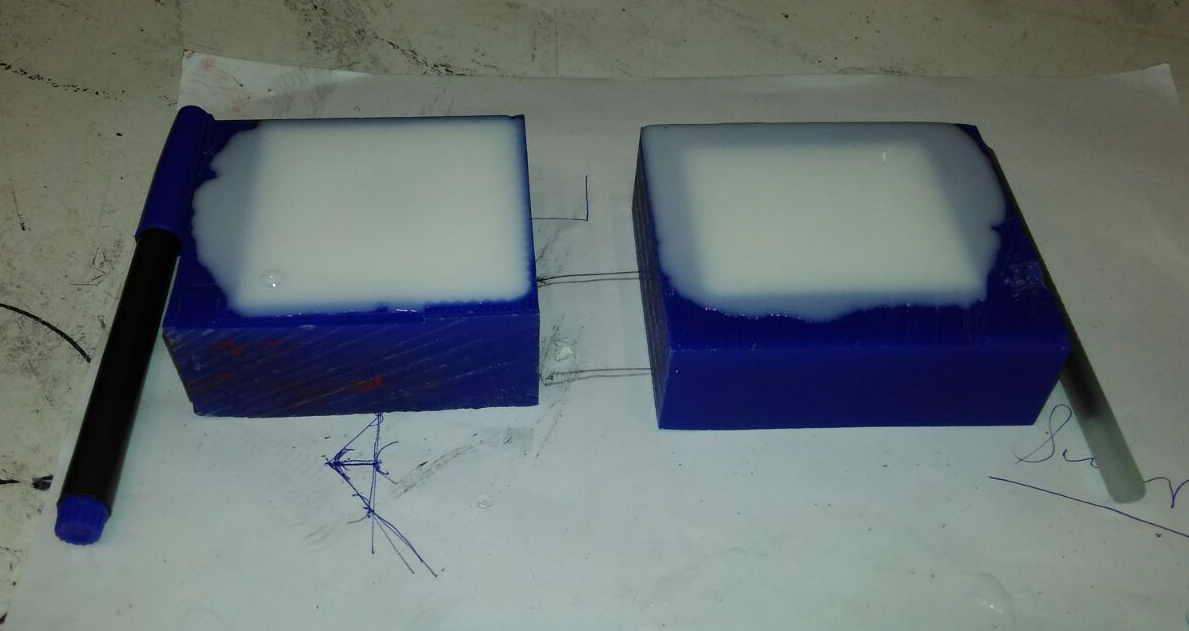

It mixed into 100:3 A & B and just pored into wax, after measuring the valume of water.

After 3hours it comes very well, I pored another time made a 2 pieces

Then just sticked the 2parts and made a small hole from upper side, Mixed the Dry stone 3:1 with water and just pored into in after 30minutes, It comes very nicely